Runruno is a conventional drill and blast open pit mining operation. The space available for waste dumps in the mine is constrained by the short strike length of the orebody and steep terrain. Consequently, the waste material from the pit is currently placed in ex-pit dumps, with the pit being developed to accommodate in-pit dumping to progressively fill the mining void. The open pit area is 600 metres x 1,500 metres, with mining taking place in stages longitudinally along the ore body to provide an average strip ratio and consistent ore delivery to the plant.

Mining Operations

Mining

How Runruno was turned around

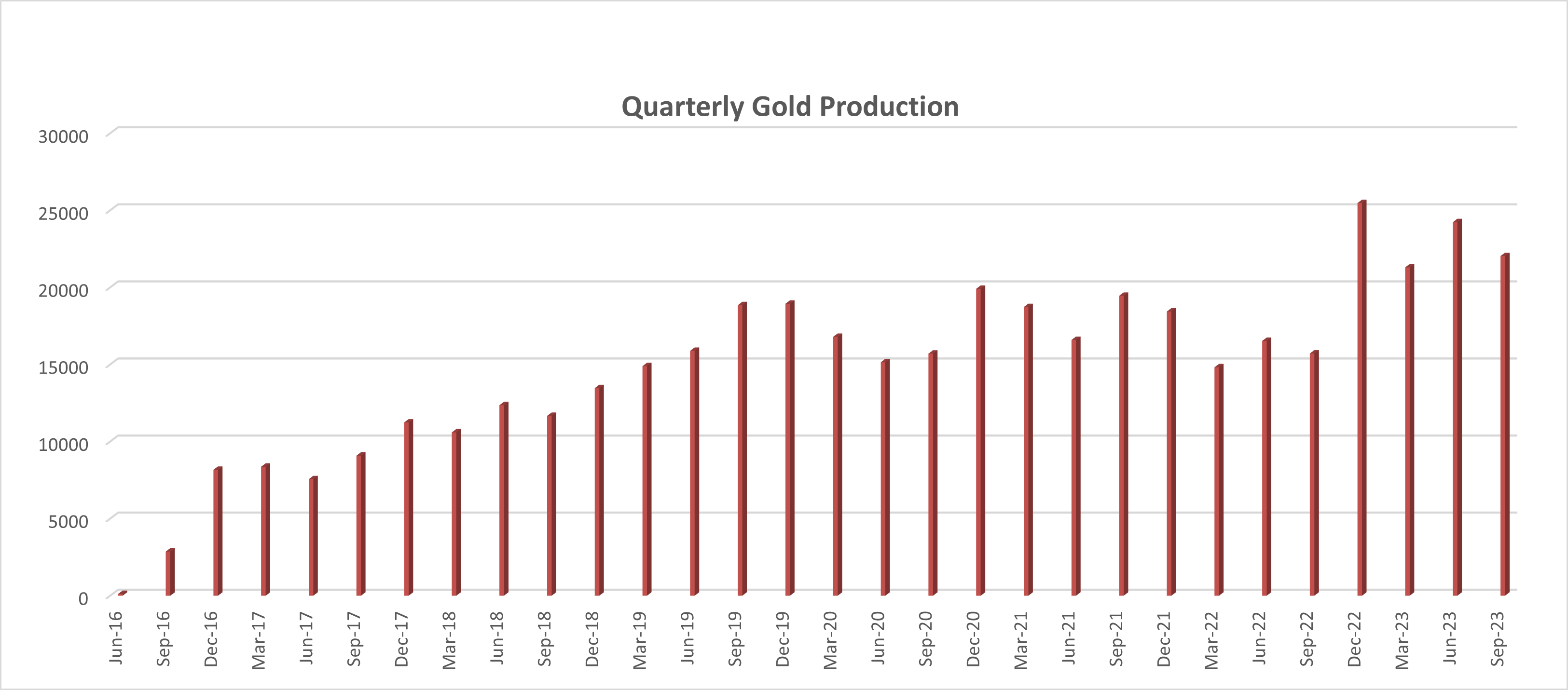

Runruno was besieged with technical problems from day one in both the mining and processing aspects of the operation. Feed grade significantly ended up being significantly lower than that projected in the feasibility study together with poor flotation performance, the BIOX® circuit was operated in the range of 40-50% of the sulfur design capacity. The management team led by Darren Bowden fixed the many technical issues at the operation to turn it into a profitable, steady state operation, as outlined below:

Optimising Mill Performance

Three core issues with the plant were identified and corrected under the new management:

- Maintenance: A lack of maintenance hamstrung Runruno significantly until the new management initiated a turn around. Maintenance reliability is critical to maintain steady state operations of a processing plant which is a requirement for the performance of the BIOX® system. Whilst chemical processes have the ability to recover quickly from short term failure and reliability issues, BIOX® does not. The new management started to undertake maintenance and upgrades of key operating and back up circuits in 2019.

- Flotation: Whilst BIOX® is widely viewed as a highly complex, sensitive technology, the primary problems at the Runruno processing plant had to do with the inefficient operation of the flotation circuit. Flotation was never recognised as a bottleneck prior until the end of 2018, once the new management came in. Significant amount of gold was not getting into the flotation circuit, with only 40 tpd of Sulphur concentrate produced versus 70 tpd design capacity. This was corrected following extensive lab testing, with pH corrected to a range between pH8 and pH9, at which flotation started to operate at design parameters. With increase in mill throughput and increase in proportion of sulphide ore in the mill feed since, sulphide feed to BIOX® reached and exceeded the design tonnes.

- BIOX® circuit: Once issues with the flotation circuit were fixed in 2019 and enhanced in 2020 and flotation concentrate feed exceeded design capacity, BIOX® performance deteriorated and became evident as the major process bottleneck. The result of the underperforming BIOX® circuit was a reduction in the CIL recovery despite optimisation and improvement in the CIL operation since April 2019. Corrections to these failures resulted in an increase of concentrate oxidation from 60% to 80%. CIL gold recovery depends strongly on sulphide oxidation in the BIOX® process.

These efforts resulted in the overall recovery increase at the Runruno mill to 90% in 2024 up from 50-60% prior to 2019. This has resulted in a huge decrease in per ounce cash costs despite the overall increase in overall yearly processing costs.

Mining Improvements

A number of improvements were made with respect to operating the Runruno open pit, which ensured the pit can operate smoothly until the end of mine life. The Runruno pit runs through Malilibeg Fault, however prior to 2019, there were no considerations for the fault in the mine design, which resulted in a number of unexpected pit failures starting in 2018, which effected the mining rates at Runruno. The new management redesigned the pit to put in a cutback, to satisfy the required factor of safety for the pit walls. This increased waste movements and stripping ratios from the original designs, however this will ensure safe and stable operation of the pit till 2026.

This has now been corrected with the redesign of the mine wide ramp system and since Q4 2021 mine waste mine has been backfilled in the stage 1 & 2 pit void, thus decreasing the amount of trucks required in the pit, lowering the overall cost base.

Finally, there was a distinct lack of definition drilling and thus the understanding of the mine reserves going forward. This has been corrected with significant money spent on reserve drilling. This has increased the confidence in the mine reserves, thus allowing for better forecasting and short and medium term mine planning.